FAQS – WPC BOARD PROCESSING, APPLICATIONS & MARKETS

| Sr. No. |

Questions |

| 1. |

Tell us regarding the raw material or inputs you use in producing your product ranges. |

| A |

We use WPC Sheets at major in all our product ranges. |

| 2. |

What are your views on Import of raw material, inputs and technology in terms of machinery or software? |

| A |

When we are using only WPC as our core raw materials, for us importing of raw materials and technology remains essential. India is still a developing market for our products and we need to source technology from Europe or Chinese markets.

Indian technology is still under development phase and as of now, we have to rely on imports.We use PVC as our basic resin and in India it is available from captive large scale players. But still it does not fulfill the total demand and we need to keep import option open. Other raw material inputs also we procure from import options. |

| 3. |

What are your personal views on GST & Demonetization reforms? |

| A |

Demonetization is surely a positive move to refurbish the economy of our country. There was a parallel economy developed because of cash transaction practices and it was hindering the growth of the country. We need fund to run a country and it can be raised from taxes only as an immediate resource. To strengthen any economy there should be minimal foreign debts and this action will lead to a positive state of debt-free country. This funds are very much needed for infrastructure developments which can shift us up in the list of developed countries. Demonetization is becoming a helping hand to the Indian government against terrorism. Banks and financing systems are expected to be revived with this move and a great level of economy growth is awaited. GST is a perfect move for restructuring the taxation system of the country. It will help entrepreneurs at first instance for smoothening their routine operations and lot of commercial headaches. GST implementation will bring high level of transparency within the system and it will make life easy for business community. Apart it will help the government to effectively control the flow of revenue. System will be cleaned after implementation of GST. |

| 4. |

Tell us about your prediction for modular kitchen market in India? |

| A |

Modular kitchen is absolutely becoming a necessity now for Indian kitchens. Well designed, engineered and equipped kitchen makes life easy for family and especially of an Indian woman. Not like conventional kitchens where material was used to be only plywood and mica and was being made by a carpenter. Today’s kitchen are made with new generation materials like WPC that is completely water proof and termite proof. It gets installed more precisely, faster and qualitatively. There are best technics, tools and hardware fittings available now from Global and Indian players and those convert kitchen making into ‘Engineering’. Indian infrastructure industry is geared to the first shift only and there are many office, residence and industrial complexes yet to be built. Modular kitchen and furniture is becoming an industry itself. |

| 5. |

Please define your manufacturing cycle/processes and tell us something about your business model and cost benefits. |

| A |

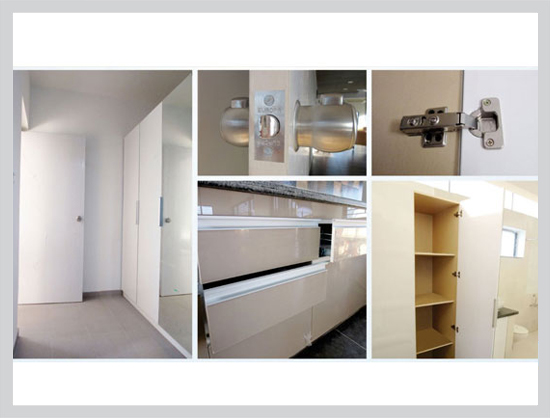

As explained, we use wood polymer composite based on PVC as our panel material. We use this material for making modular furniture on panel processing machines. Using Italian Panel saw, Thrufeed Edgebander, Presses and hand tools WPC based furniture is made with PVC solvent mechanism. Material is 100% water proof, 100% termite proof, 100% borer proof and 100% recyclable. We use natural panels from our captive brand ‘HARDYPLAST’ for carcass applications. Shutters we make with PU and PVC marbles. PVC marbles are replacement product for natural veneer with PU and HPL. Modular furniture we make with WPC material has a long life and non-absorbent surfaces, thus furniture made remains clean and green for longer time. Cost wise our material remains cheaper against waterproof plywood/Marine plywood. For carcass there is no need of applying HPL or paint on the surfaces, thus it also saves lot of cost including material, labour and time. Being 100% recyclable material, we offer buy back guarantee with 25% money back after 3 years if sold back to the company. WPC is our core business and we do material and applications. |

|