The journey of WPC in India, reaching 15th year. This year, the WPC market exceeded 10,000 Cr INR/1.15 billion USD, against global market of 10.5 billion USD. More than 1000 extruders have been set up across the country. 1.70 MMTPA is the installed capacity of India today with WPC machines. Funding is being poured from small startups and large corporations, both. There is a growing investment in PVC based WPC products.

India makes WPC | India uses WPC | India demands WPC

India has more versatile usage and applications of PVC based WPC compared to other part of world. Intense usage methods and patterns are found in the country those are influenced by the culture. Innovative designs are adapted to local needs and applications across the Rual and urban plethora. Numerous opportunities are evolving the in developing markets of India for WPC. India’s 1.46 billion Population serves as a key strength for larger market share, globally.

A huge replacement is forecasted for Wood

India‘s wood market size is estimated to be USD 16.07 billion in 2025. Massive replacement is forecasted for wood and allied products with WPC. Technical properties of WPC cater in resolving fundamental issues of wood like moisture, termite, fire, wastage and most important is wood’s use with surface preparation only. WPC is finding acceptance with applications ranging from carpenters to large construction firms. Today, WPC is being utilized notably by both private and public sectors for building and construction applications.

Booming construction markets of India

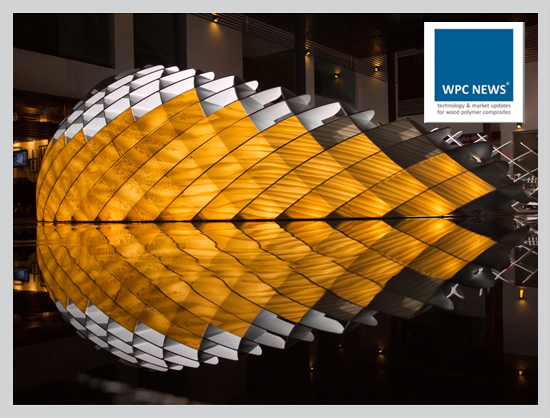

Indian construction market is expected to reach to USD 2134.43 billion by 2030. As of March 2025, RERA in India has 1,43,000 projects registered comprising of 11.1 million construction units. Multistorey Apartment market is experiencing cultural shift with Large, multi-bedroom high-rises in demand across all the tires. The redevelopment sector is in momentum and that is one major driver in construction sector as well. For an example, Ahmedabad as the 7th largest Indian city with 9.06 million population has 400 redevelopment projects in negotiation. It shows the intensity and volume.

Massive demand is projected for Sustainable furniture materials

The country’s rising land prices will necessitate vertical developments. With this, India’s Furniture demand is projected to reach USD 25.75 billion in 2025 and Interior design market to reach USD 35 billion by 2025. Spending on the home Interiors is increased and matches to the building unit costs in cases. As disposable income rises for the middle class, spending power increases on property buying and lifestyle purchases. Demand is growing for smarter, faster, and sustainable materials that can deliver furniture in no time. Culture influences families to be nuclear, resulting in increased buying of houses, especially apartments.

Manpower crisis of today and future

Demand for skilled workers in India is 103 million and supply is 74 million only! Skilled manpower for machine operating to the product installations are becoming scarce. Factories may have orders but deliveries to be addressed in time, may become a challenge. You may have materials ready, but site installations…again a challenge! Developing IT, Retail and Food chain sectors are enjoying shuffling of manpower from hard core sectors. Thus, skilled labours/artisans are reducing, massively. Here India will need smart materials like WPC.

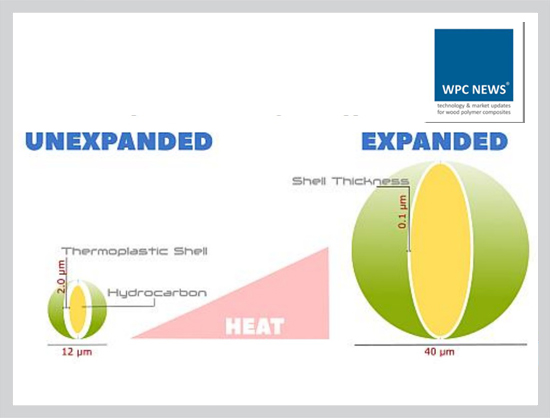

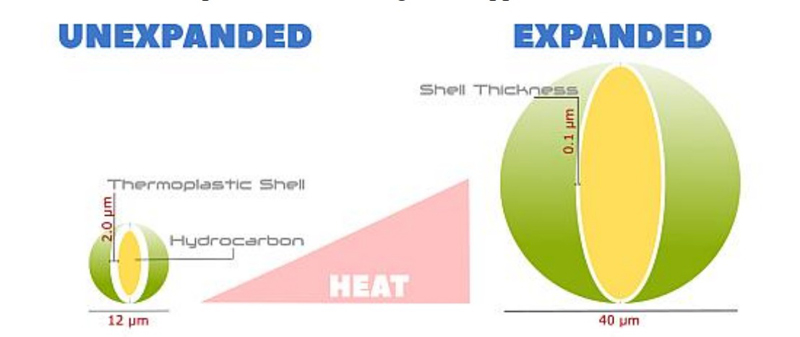

WPC – a product for Indian markets – Smarter, faster, designer in Indian way

WPC becomes compatible with its faster making, easy joineries and faster installation possibilities, that leads to less project hand over time. Its glue joinery with cyanoacrylate can create an era in furniture making.

Opportunities for Global WPC Technology suppliers

INDIAN FORECAST for WPC technology sector says there will be500 new lines will be needed in next 5 years. There are no local WPC technology manufacturers, thus India needs good extrusion lines from the other part of the world. Bigger capacity machines are a NEED of the HOUR for WPC sheet and profile extrusion technology markets.

INDIAN OPPORTUNITIES stands with Machines, Dies, Screws and Spares. Global players can bring into Technical/Technological collaborations and Joint ventures with Indian players sharing their expertise and enjoying the booming market share here. Manufacturing startups and investments can be planned in India for above products as well as in AI/Robot based material handling.

Opportunities for Global WPC product suppliers against INDIAN DEMANDS

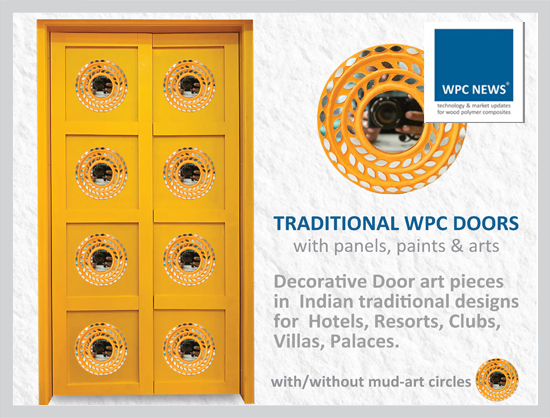

Door & Window – USD 7.3 billion by 2025. Façade demand – USD 5,578.3 million by 2033. Wooden flooring – USD 85.15 million by 2025. Public sector projects – USD 11.1 trillion by 2025. Housing projects – USD 150 billion by 2025. Residential projects – USD 205 billion by 2025. As a figure of interest, Inventory of 1 million residences was ready in 2024.

Indian opportunities stand with the Direct product supplies, Partnerships with Indian brands, Manufacturing investments FDI, Collaborations & technology transfer route.

PVC – taking a strong space in W-PVC sector as W-PVC in Interiors, W-PVC in Exteriors, W-PVC in Modular Furniture, W-PVC in Decorative products and many more.

What Vinyl based WPC Industry needs to create a larger show?

Indian WPC Industry needs Lamination Technologies & materials, Adhesives/Adhesive systems for WPC Panels to HPL, WPC Panels to wood veneers, WPC Panels to Acrylics, WPC Panels to Vinyl sheets. The WPC industry needs good brands and materials for Paints & Coatings for WPC surfaces.

Cumulatively, vinyl-based WPC Industry is flourishing in india in all around demands from villages to cities. Taking from the WPC Door frames to the Exterior facades WPC is creating a solid space. There are a few known but strong and responsible brands are leading the market with best products, with consistent quality and standard raw materials. Vinyl based WPC products are sustainable and can make the future sustainable.