By Hadik Panchal, HARDY SMITH, India.

B. Eng. Polymer Technology, LDCE, India. MBA, AESPGIBM, India.

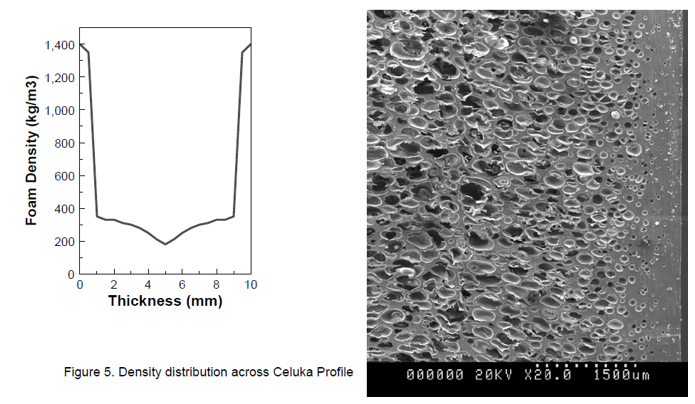

PVC is a popular material with different combinations including wood. It forms a composite with celluka foam structure. Carrying a basic density of 1400 kg/cum PVC is the most suitable material for rigid foam profiles including wood. One of such popular profile is Solid WPC PVC Door frame profile.

DENSITY can be defined as a range and not just as a fix figure, technically. It can be well understood while reading this article.

Density of a foamed PVC material has many influences during the entire process of extrusion. The melt that develops inside the extruder barrel because the temperature and friction of screw carries a melt temperature. This melt temperature varies at different zones of extruder. Now this melt is carrying foaming agents and foam modifiers those are actually creating a cell structure. The melt passes from the screw barrel zone carries a certain temperature, then passes through the Die head at a different temperature and then moves out to a calibrator at a different temperature.

All it’s passes impacts the foaming of the material. Now apart from the internal temperatures and speed, external temperature and moisture are also playing the very crucial role on the density formation/cell formation of the material. Formulation of the material remains to be the pre-defined content with all precisely calculated and weighed additives and chemicals. This formulation is being designed to manufacture a specific density range of a solid foamed product. Final material coming out of the Die head and calibration passes through the cooling water for settling the cell structure for perfect physical form. At the end frames are getting stacked for storage and here the final settle down happens under atmospheric temperature. At this stage also several internal movements inside the material happens and gets hold, finally.

During this entire journey of the material the Density profile of the PVC Foam keeps changing at several stages:

- Keeps changing with the melt movement

- Keeps changing with the extrusion screw speed

- Keeps changing because of the motion of the material,

- Keeps changing because of cylinder zone temperatures

- keeps changing because of adapter, flange and die temperatures

- keeps changing because of settling of the outer layer first and semi cured ‘core layer’ yet,

- keeps changing because of water temperature now,

- keeps changing because of atmospheric temperature again,

- keeps changing because of moisture of the atmosphere,

- keeps changing during the final curing and settling down at store.

All in all, the production of foamed PVC itself is a complex mixture of thermal stabilizers, lubricants, processing aids, pigments, fillers added with blowing agents to foam a cellular structure. The ‘type of PVC and the ingredients used’ control the thermal stability, gelation behaviour, powder flow characteristics, melt viscosity and melt strength during the production process. Hence all components of the formulation and process influence the subsequent foam Density

Now logically and technically if this process is understood by technocrats, Density of the entire material cannot be fixed with one fix figure of 750 kg/cum. It cannot be stopped/hold/fixed on this figure of so called 750…and thus moves upto 850 as well and can be 700 as well. As a part of the best manufacturing practice can be defined with 5% +/- density variation is really the best.

References:

- Handbook of Polymer foams David Eaves, UK, Rapra Technology Limited.

- Standard Test Method for Apparent Density of Rigid Cellular Plastics ASTM-D1622-D1622M-14-2008

- PVC Foams by Gupta-Verlag

- In line density monitoring by N H Abu-Zahra and H Chang

- Specific modulus and density profile as characterization criteria of prefab wood composite materials, Dept of wood science, Mendel University in Brno, Czech republic

- Rigid PVC Foam: A study on blowing agents and processing aids by N L Thomas & R P Eastup, European Vinyl Corporation (UK) Limited, UK.

- Cellular PVC-U: Current Technology and Future Challenges by N. L. Thomas, Institute of Polymer Technology & Materials Engineering, Loughborough University, UK.

- Characterisation of thermal expansion behaviour of a PVC foam core: Non linearities and gradients across the width by Pascal Casari, Carols Ferreira and Frederic Jacquemin, Institute of research, France